Conveyorized Poultry dressing or slaughter Plant

Poultry Processing Plants are Conveyor – based chicken slaughter plants having an overhead conveyor and full range of process machinery. The birds are dressed on the conveyor through all the important stages of processing such as stunning, halal, hot water scalding, De-feathering, evisceration & chilling etc.

The conveyor based operations and scientifically designed machinery ensure highest levels hygiene and give the best quality of meat.

They are designed for dressing capacity of 1000 Birds Per Hour (BPH).

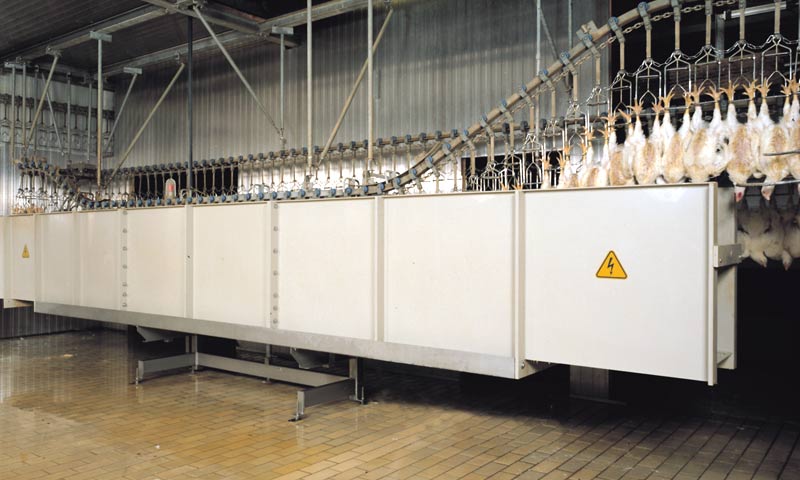

Electric Stunner

Electrical Stunner machine that cater to the requirements of poultry industry

It is a device used in abattoirs to stun an animal in order to make it unconscious when it is bleed out.

Robustly constructed, our electric stunner is ideal for small animals.Further, these can also be made as per the specific requirements of the clients.

Use For:

It is a device used in abattoirs to stun an animal in order to make it unconscious when it is bleed out.

Hot Water Scalder Conveyor Model

The hot water Scalder for Conveyorized plant are of Continuous type. They are made in different sizes suitable 1000 birds per hour capacity. Scalders have different heating and agitation options depending on capacity. They are made in stainless steel and play a crucial role in scientific & hygienic processing of poultry. These scalders have electronic controls for maintaining the temperature of water with in a close range.

Our scalders are efficient in scalding chicken in a clean, fast and easy manner. We can also customize these scalders in terms of temperature controls, agitation mechanism, design and capacity.

- Its a conveyor based hot water scalder.

- Offers scientific & hygienic poultry operations.

- Efficient in scalding chicken in a clean, fast and easy manner.

- It can be customized.

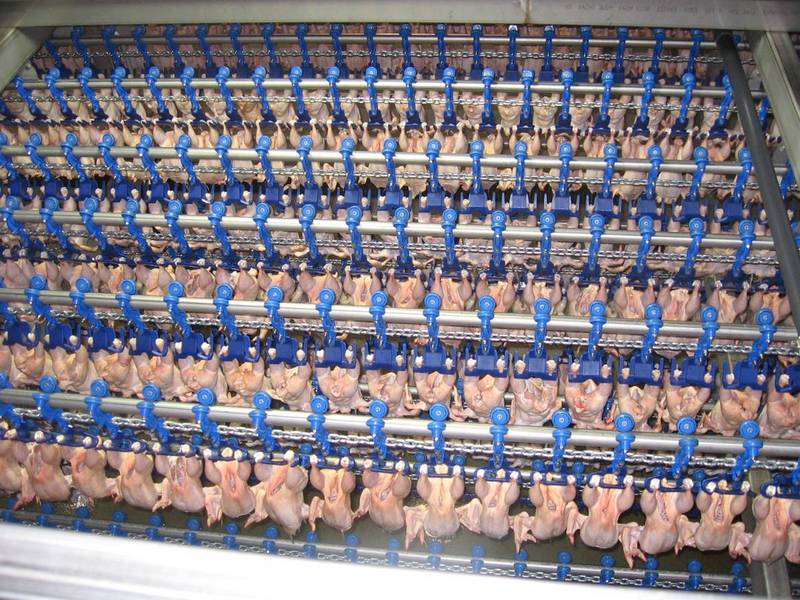

Feather Plucker

Feather Pluckers that are used by broiler farmers for poultry operations.

The machines we make having four way adjustments for flexibility of plucking different sized birds from 1.0 kg to 3.0 kg (Live wt.). Made in food grade stainless steel, it has all the provisions for giving best feather plucking jointly with our Hot water Scalder. It also called as De-feathering machine. The Feather pluckers are fitted with specially made food grade rubber fingers.

Features:

- Conveyor based feather plucker

- Plucking different sized birds from 1.0 kg to 3.0 kg (Live wt.).

- Specially made up of food grade rubber fingers.

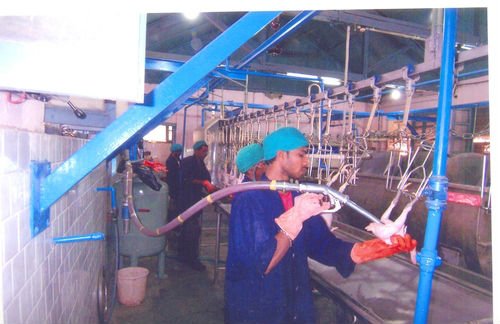

Lung Suction Gun

Lung suction gun removes the lung from inner cavity by vacuum suction. This operation removes lung as well as other residual matter inside the bird carcass.

Uses of Suction Gun:

- Vacuum Lung Suction Gun used to remove lung as well as other residual matter inside the bird carcass.

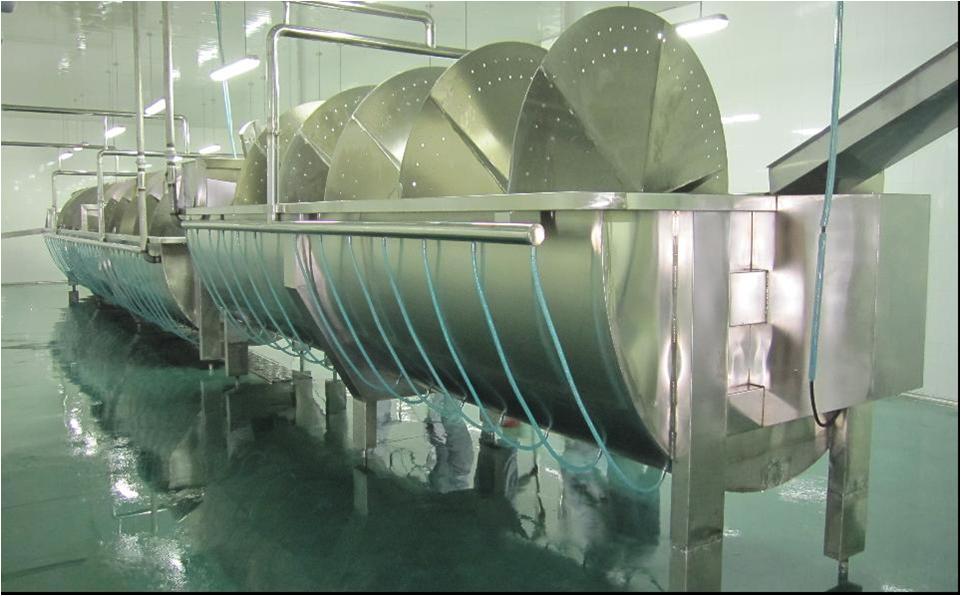

Screw Chiller

Screw Chillers are made of food grade stainless steel to suit the processing capacities 1000 birds per Hour. This equipment is used to chill the bird after the process of scalding and De-feathering so that it can be made ready to be stored. On the request of our esteemed client, we also provide a Packaged Water Chiller to supply uninterrupted flow of Chilled water.

Features:

- Screw Chiller made in food grade stainless steel

- It can process 1000 birds per Hour Processing unit consisting of Drip Roller drum, Portioning machine & Vacuum packing machine etc.

- All the equipment / machinery are made in food grade stainless steel for maintaining most hygienic conditions in the meat processing area.

Chilling

Simply put, the chicken is chilled with air, not water. Traditionally chicken is chilled in water.

Pine Manor chicken, both Antibiotic Free and Organic is air-chilled. This simply means it uses a different cooling system in that process to chill the chicken. The air chilling process takes the chicken into a large cooler of air that circulates cold air throughout the room sealing in the flavor and giving it a more genuine chicken flavor. The closely monitored cooling chambers chill the chicken so there is no extra absorption of water. Western Europe and Canada have been using this method for years and believe it results in more genuine chicken flavor which is moist and tender.